testo 191 HACCP data loggers

|

| 1 The testo 191 HACCP data logger for process validation and qualification Validating sterilization, pasteurization and freeze-drying processes |

The testo 191 data loggers for pressure and temperature were specifically developed for use in the food industry, certified by HACCP and also compliant with EU 1934/2004.

With practical advantages, such as the rigid and flexible probes, these compact measuring instruments will help you to qualify your systems in compliance with the standards.

The data loggers feature a wide temperature measuring range, from -50 °C to +140 °C, and measure pressures from 1 mbar to 4 bar, which means that you can work reliably in the tough environments found in food production.

testo 191 : Your advantagesat a glance

– Robust : Successfully tested for reliable operation from -50 °C to +140 °C during more than 1,500 operating hours

– Reliable : Intuitive battery replacement with no tools – impossible to assemble incorrectly

– Protected : Electronics in glass-metal bushing impervious to water

Overview of all testo 191 HACCP data loggers

testo 191-T1 HACCP temperature data logger

• Applications: Pasteurization, sterilization

• Application range: -50 to +140 °C

• 1 probe (rigid): Ø 3 mm; length 25 mm

testo 191-T2 HACCP temperature data logger

• Applications: Pasteurization, sterilization

• Application range: -50 to +140 °C

• 1 probe (rigid): Ø 3 mm; length 115 mm

testo 191-T3 HACCP temperature data logger

• Applications: Freeze-drying, sterilization

• Application range: -50 to +140 °C

• 1 probe (flexible): Ø 1.5 mm; length 775 mm

testo 191-T4 HACCP temperature data logger

• Applications: Pasteurization, sterilization

• Application range: -50 to +140 °C

• 1 probe (rigid): Ø 3 mm; length 25 mm

testo 191-P1 HACCP pressure data logger

• Applications: Pasteurization, sterilization

• Application range: 1 mbar to 4 bar abs.

• Application range: 1 mbar to 4 bar abs.

• Application range: 1 mbar to 4 bar abs.

The testo 191 Professional software: Intuitive and clearly structured

Most software solutions for data loggers used for validation and qualification in the food industry are confusing and complicated. Thus, when developing the testo 191 Professional software, we particularly focused on making it as intuitive as possible to use. Because we believe that our data logger software is supposed to reduce your workload rather than increase it.

Advantages of using the testo 191 Professional software

• Preset process templates with guided work steps

• Flexible evaluation of multiple or individual measuring cycles in just one click

• Simple implementation of key calculations (e.g. holding phases, lethality, saturated steam quality)

• Target/actual comparison of freely definable acceptance criteria

• Visualization of the measurement set-up

• Fast and comprehensive report generation

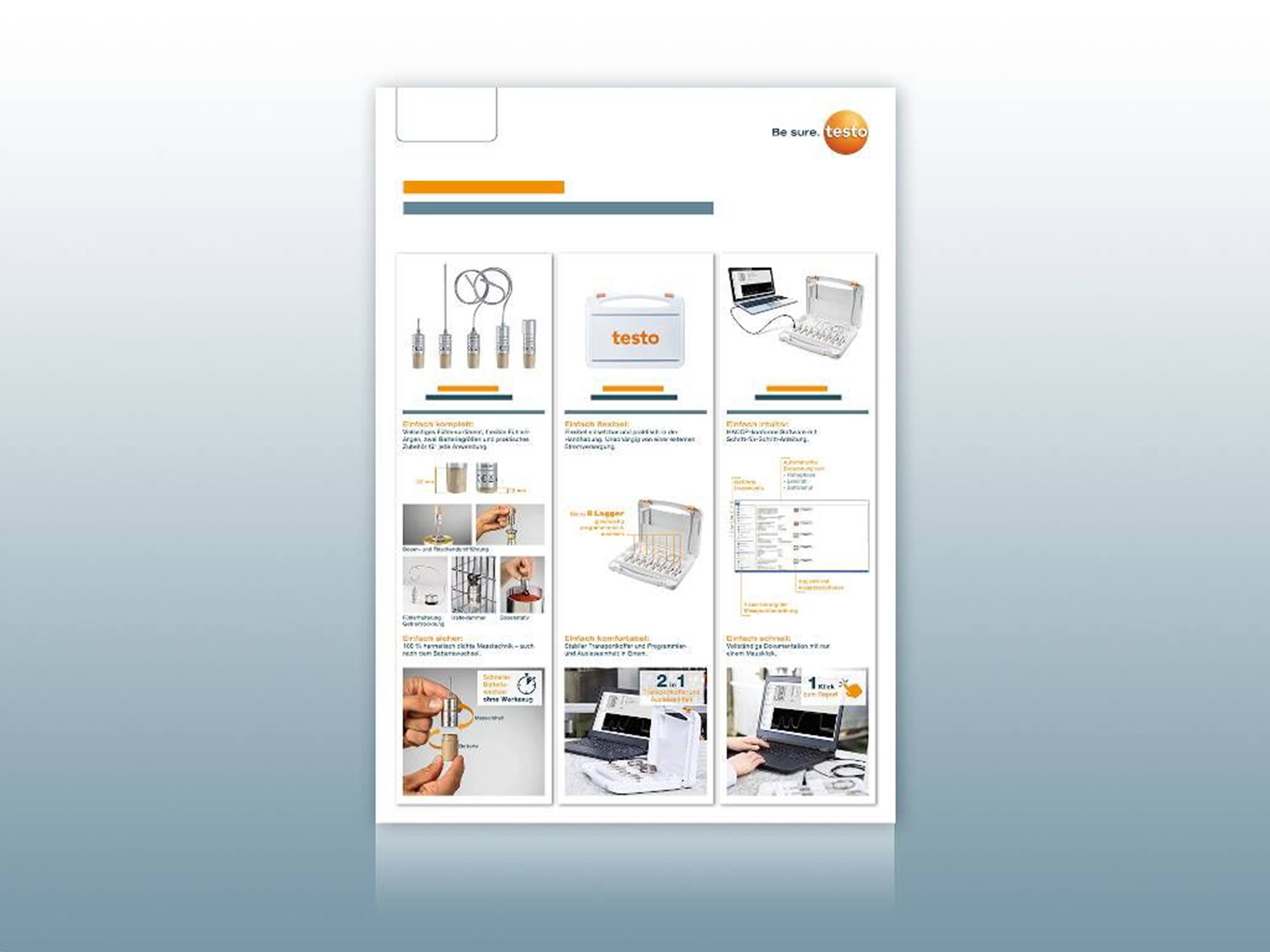

Your advantages at a glance

Intuitive programming

Configure up to eight loggers in parallel – exceptionally efficient thanks to guided processes.

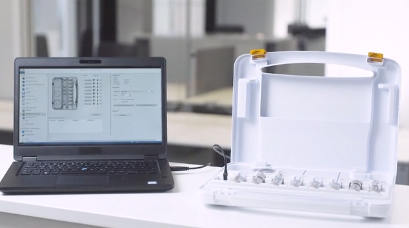

Fast readout

Unobstructed readout of the data loggers via secure positioning.

Safe transport

Protected transportation of the loggers in the built-in readout unit.

How the testo 191 Professional software works

Programming of data loggers

Readout of data loggers

Visualizing the measurement data

Defining calculation

Defining acceptance criteria

Analyzing results

Visualizing the measurement set-up

Configuring and creating reports

Downloads PDF