NEO HSX ONE

Product Descriptions

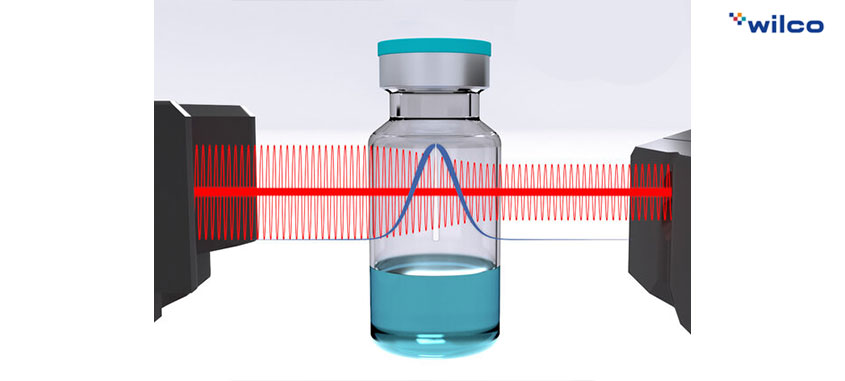

The NEO HSX ONE is a system for the non-destructive measurement of gas concentrations such as oxygen and carbon dioxide in the headspace using laser absorption spectroscopy. The oxygen analyzer and carbon dioxide analyzer can test vials, syringes and ampoules or other packaging used for sterile pharmaceuticals. NEO stands for our new generation of compact inspection systems bringing sensitivity, usability and flexibility to the next level.

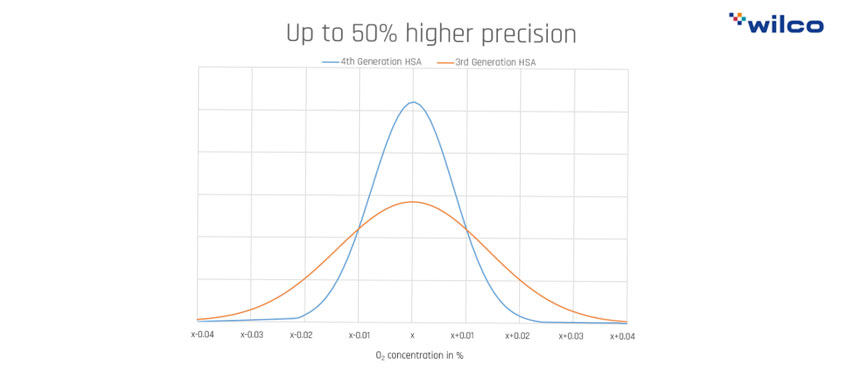

The new laser generation achieves a 50% lower standard deviation, which enables more accurate and faster processes and thus new applications. Due to the short measurement times, a transfer of the test method to a corresponding high-speed production line is even easier. Various lasers are available for the non-destructive measurement of O2 and CO2 concentrations. These enable leak tests, media fill inspections or residual oxygen measurements for a wide variety of pharmaceutical packaging.

Supported operator guidance

The WILCO user interface MAVIS supports the user during operation. Similar to a smartphone, the user can use widgets to display personalized content on the 12.1″ color display. The operator is guided step-by-step through the menu for both inspection and format change. An LED bar provides visual orientation on the process step. The operator guidance ensures consistent and user-independent testing.

High process reliability

Different sample holders are available for the different applications, which verify the settings previously defined by means of the position monitoring system. The system has two modes: a development mode for the definition of recipes and less critical measurements, and a mode for measurements in the GMP area for the highest safety requirements.

Specifications and highlights

– Position monitoring of sample holder

– Shield for protection of environmental influences

– Versatile use in terms of packaging and product types

– Three different wavelength available (O2/CO2)

– Latest 4th generation headspace analysis systems

– Exchangeable sample holders (plug&play)

– Spinning of samples during testing

– Intuitive operator support by LED status bar

– Guided system suitability test (SST)

– Operator independent test results

– Customizable interface by means of widgets

– Recipe management for versioning and release

– One-hand operation with operator guidance system

– GMP testing and development mode

– Integrated UPS for prevention of data loss

– 21 CFR part 11 compliance

– Certified for use in ISO Class 7 environments

– OPC UA server connectivity