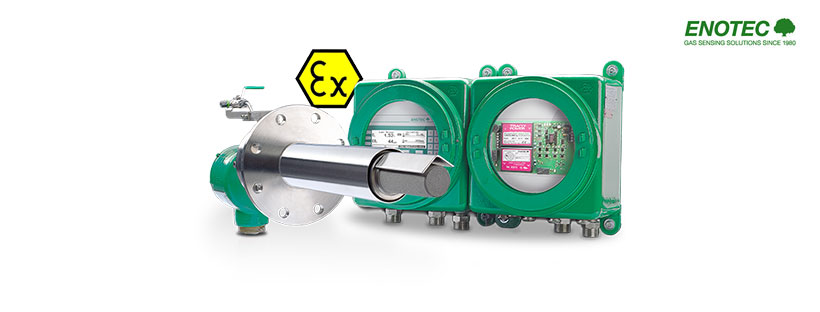

COMTEC® 6000 GasEx : O2 Analyser

Product Descriptions

The COMTEC® 6000 GasEx is an Ex protected analyzer for safe measurement of oxygen and combustibles in gas hazardous environments (gas explosion zones 1 and 2).

The explosion protected gas analyzer COMTEC® 6000 GasEx reacts immediately to process gas changes and is ideal for safe and exact measurements of oxygen and COe in refineries or similar areas with explosion hazards (Gas Ex zones 1 / 2).

The COMTEC® 6000 GasEx fast flue gas analyzers are ATEX (II 2G Ex d IIC T3/T6 Gb) certified by a German test institute whereby the certifications encompasses the complete analyzer, including parts in contact with process gas. This certification builds trust in plant security. This is coupled with ENOTEC’s compelling product quality, which is continually able to withstand the challenge of aggresive process conditions.

Applications

– Refineries

– Ex hazard installations

– Petrochemical plants

– Gas by-product/Mixed gas furnaces

– Natural gas liquefaction plants

Features

– InSitu measurement in real-time

– Overview of calibration history

– ATEX certification

– Low-maintenance design

– Self-monitoring

– Sensor life expectancy on display

– Gas tight sensor construction

Technical Data

| Insertion depth of probe | 464 mm 924 mm |

| O2 / COe ranges | 0 – 25 % O2 min.: 0-1000 ppm / max.: 0-5000 ppm COe (others on request) |

| Sensor accuracy O2 |

< 0.5 % of measured value or 0.02 Vol % O2 (higher value valid) |

| Sensor accuracy COe | better 5 % of range end |

| Reaction time |

< 1 sec. (on test gas) |

| Process gas temperature |

max. 500 °C max. 1400 °C (with cooling protection tube) |

| Ambient temperature | -40 °C to 70 °C (probe) -20 °C to 55 °C (electronic unit) |

| Interface | MODBUS RTU via RS232/RS485, HART, FIELDBUS, ENOTEC REMOTE |

| IP code | IP65 (probe) IP66 (electronic unit) |