850 Fuel Cell Test System

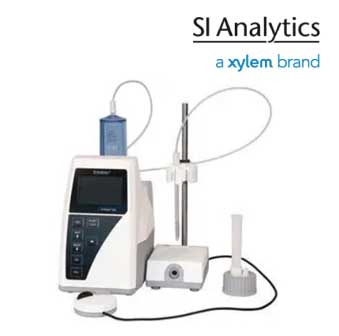

The model 850 Multi-Range Fuel Cell Test System is a complete test station for operation and measurement of PEM/DMFC fuel cells. The 850 is ideal for single-cell and short-stack fuel cell research and university programs.

The 850 combines a computer-controlled instrument with fuel handling hardware in an integrated bench-top unit. The 850 uses the proven 890 as the basis for the electronic load design. The powerful FuelCell® software package is included for controlling station operation.

• Multiple current range electronic load choices: 5/25/50 A or 10/50/100 A, 100 W, 20 V

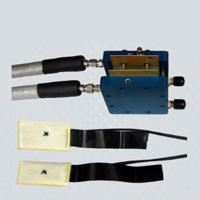

• Suitable for up to 50 cm2 PEM cells.

• FuelCell® software for user-friendly computer controlled cell operation & experimentation

• Temperature controlled high performance 316L stainless steel humidifiers, and heated gas transfer lines

• Computer control of anode and cathode mass flow rates

• Automatic control of N2 purge gas to cell

• Detection of pressure loss for reactant and purge gasses

• Current, voltage or power control modes

• Continuous real time cell resistance and IR-free voltage measurement by Current Interrupt

• Whole cell voltage plus two high-impedance reference inputs for half-cell data

• Cell main terminals and sense inputs tolerant of a non-isolated cell

• Automatic Water Fill for humidifiers

• Safety features include detection of alarm conditions and automatic hardware

| Electronic Load: | |

| Maximum Load Current | 5/25/50 A or 10/50/100 A (configuration dependent) |

| Maximum Load Power | 100 W |

| Minimum Load Resistance | < 2 mΩ (100 mV @ 50 A at load terminals) |

| Current Resolution | 1 mA for 5/25/50 A; 10 mA for 10/50/100 A |

| Current Accuracy | 0.3% of full scale current of selected range |

| Voltage Measurement and Data Acquisition: | |

| Max . Whole Cell Voltage | 20 V |

| Max . Reference Electrode Voltage | 9.999 V |

| Voltage Resolution | 1 mV |

| Voltage Accuracy | ±3 mV ±0.3% of reading |

| Voltage & Current Data Update Rate | 100 Hz |

| Whole Cell Sense Input Resistance | > 35 kΩ |

| Reference Electrode Input Resistance | > 109 Ω |

| Impedance Analyzer (Optional 881): | |

| Internal Impedance Analyzer Type | Single sine, one generator and two gain/phase measurement channels |

| Internal Analyzer Frequency Range | 1 mHz to 10 kHz |

| Measurement Channels | Three: whole cell plus two half cell vs. Reference Electrode |

| Temperature Controllers | Three: cell, anode humidifier, cathode humidifier |

| Set & Report Accuracy | ±0.25% of span, ±1 least significant digit |

| Sensor Type | Thermocouple, Type T for cell (Type K optional for high temperature) |

| Humidifiers | Dual sparger-type, passivated 316L, 360 W heaters per bottle |

| Temperature Range | Ambient to 99 ° C; Optional: 120 ° C |

| Environment: | |

| Operating Temperature | 5 to 35 ° C |

| Power Source | 120 V, 50-60 Hz, 10 A (Export model 220-240 V, 50-60 Hz, 5 A) |

| Enclosure Type | Single bench top enclosure |

| Size and Weight ( H x W x D) | 18” x 11” x 19” (+ 11” for heated gas lines); |

| 50 lb .46 cm x 28 cm x 48 cm (+ 28 cm); 23 kg | |

850e (Tan) Fuel Cell Test System Installation

850 (Gray) Fuel Cell Test System Installation

Installation of the 885 Fuel Cell Potentiostat